TWO DAY COURSE: January 25 & February 1st, 2023 from 8am to 4p. VILT: Virtual Instructor Lead Training, via ZOOM.

Click PURCHASE COURSE above to log in or set up account.

These OSHA Outreach Training courses serve as a preliminary or basic platform for the VPPPA’s 2023 Safety + Symposium and the introduction of a new premium educational program.

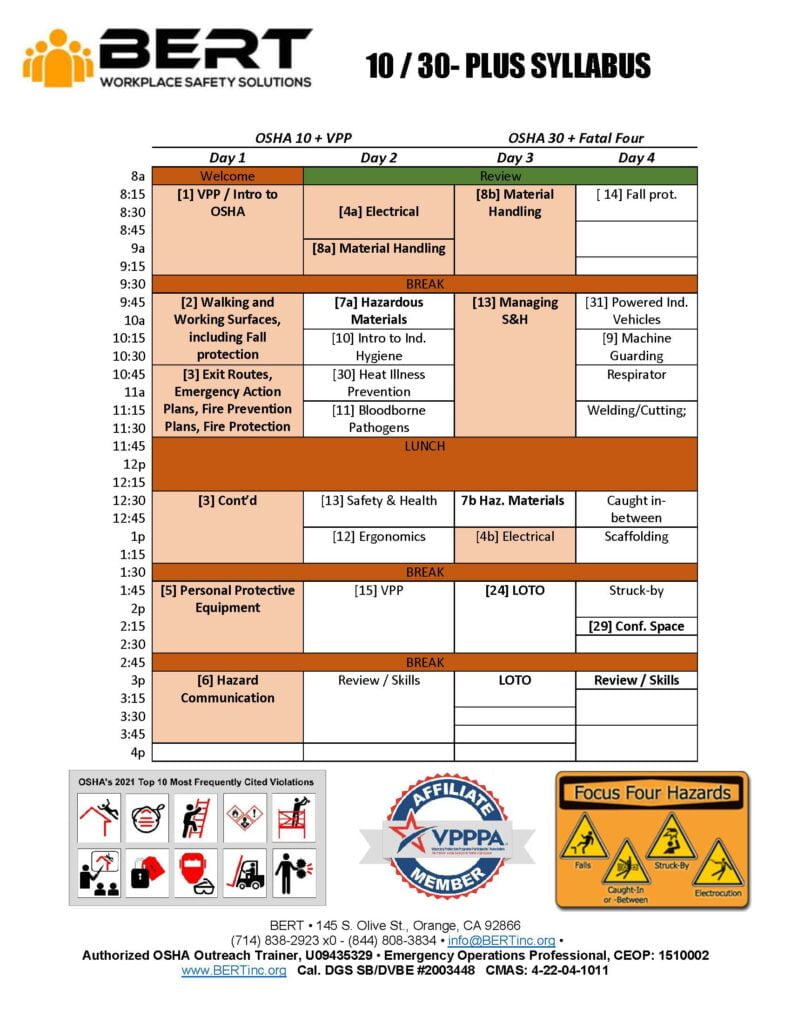

THIS IS 10-HOUR – enhanced. The course is actually 12-hours of learning time to incorporate VPP concepts.

BERT’S OSHA Outreach Training General Industry offers your employees OSHA’s 10-Hour course taught by authorized trainers PLUS an ADDED two-hour unit on the Four Elements of a VPP Star Program that reaches above and beyond the minimum requirements of OSHA standards. Each of the lessons builds back upon the VPP framework.

For discounts or ACH transfer, contact: 844/808-3834×2 or [email protected] or <contact us>

ONCE PURCHASED YOU WILL RECEIVE EMAIL FROM INSTRUCTOR WITH DIAL IN INSTRUCTIONS. OSHA REQUIREMENTS INDICATE THAT CAMERA MUST BE ON AT ALL TIMES AND FULL ATTENTION MUST BE GIVEN TO LESSON AND INSTRUCTOR. THERE IS A PROCTOR THAT WILL BE MAINTAINING COMPLIANCE. THE COURSE WILL BE RECORDED FOR POTENTIAL OSHA REVIEW.

In addition, the “enhanced” 30-hour General Industry course lessons provide a natural synergy to the site’s VPP plan specifically designed for management, supervisory, and safety team members. Using OSHA Authorized General Industry Training and credentials is a powerful foundation for employees to begin, develop, and enhance their knowledge for supporting your site’s journey.

As you know, VPP statistics show that almost 100% of employers who achieve VPP status see an increase in profits and morale.

BERT’s courses are among your best investments in your business and worksite.

Enhanced for VPP and customized to your site

-

- VILT, Live or 50/50 for least disruption

- Up to 23 people/class

- Not cookie cutter, or hours of computer-droning on

- Helps Meet VPP Continual improvement requirements

- Combine Facilities or Other Operation

- VPP priority scheduling